Freeform, a startup developing AI-native metal 3D-printing systems, has raised $67 million in Series B funding to scale its advanced manufacturing platform. Investors include Apandion, AE Ventures, Founders Fund, Linse Capital, Nvidia's NVentures, Threshold Ventures, and Two Sigma Ventures.

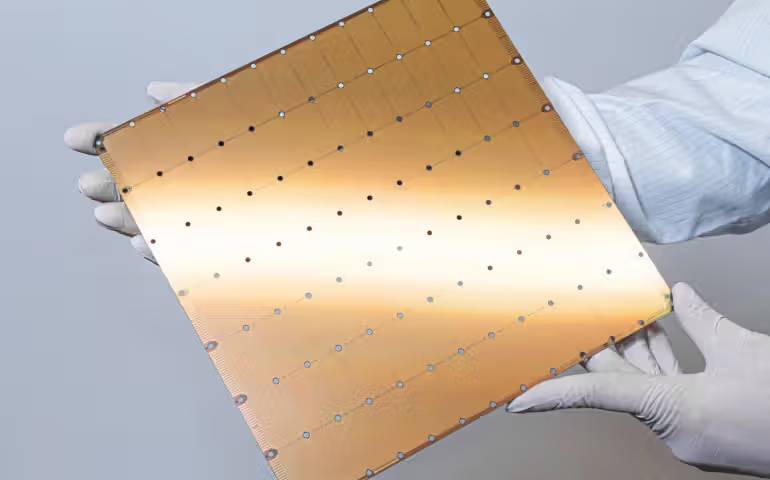

Founded in 2018 by former SpaceX engineer Erik Palitsch, Freeform addresses the limitations of traditional metal printing with its GoldenEye system, which uses 18 lasers to fuse metal powders into precision components. The company is already delivering hundreds of mission-critical parts weekly to customers.

The funding will accelerate development of Skyfall, Freeform's next-generation platform scheduled for the first half of 2026. Skyfall will employ hundreds of lasers to produce thousands of kilograms of metal parts daily—expanding current capacity by over 25x and broadening material offerings by 10x.

Freeform's "AI native" approach leverages Nvidia H200 GPU clusters for real-time physics simulations and process optimization. "We have more meaningful data on the physics of the metal-printing process than any company in the world," said head of talent Cameron Kay.

The company plans to hire up to 100 employees and expand its Hawthorne, California facility to meet growing contract demand in the emerging manufacturing-as-a-service sector.

Comments