EthonAI recently launched its Manufacturing Analytics System (MAS) in parallel with the announcement of the completion of a successful $16.7 million Series A funding round led by Index Ventures, with the participation of General Catalyst, Earlybird, and Founderful. EthonAI aims to change the fact that, even as factories generate increasing amounts of data thanks to sensor technology, manufacturing continues to lag behind other industries like logistics and finance in adopting data analytics solutions. More importantly, data analytics could aid in mitigating waste and supporting factory personnel to make better data-driven decisions to optimize growth and drive customer satisfaction.

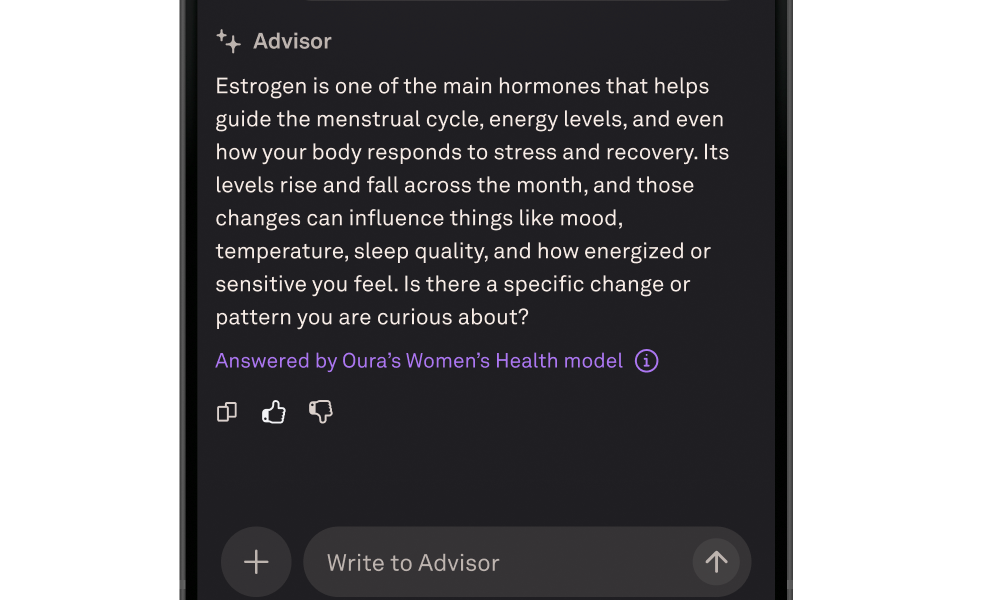

EthonAI's MAS is an AI-powered platform that ingests data from sensor measurements, order documentation, and computer vision imagery to create a real-time snapshot of the factory's operations. The MAS can spot defects and inefficiencies, predict issues, and recommend actions based on these reports, delivering "a sixth sense" to engineers and managers. By driving operational excellence, MAS helps factories tackle the waste problem that some reports describe as severe as affecting every fifth dollar spent in manufacturing. As a consequence of waste reduction, the system also enables organizations to grow margins and customer satisfaction.

EthonAI already caters to a customer base including several Fortune 500 companies and industry leaders in diverse fields, including Siemens Smart Infrastructure and Lindt & Sprüngli. Siemens applies EthonAI's MAS to prioritize quality control and value stream analysis. The MAS has enabled the company to replace isolated solutions that led to a lack of standardization with "a modern suite of interoperable tools." Siemens will roll out EthonAI's platform at additional factories across locations in Europe and the US. Similarly, Lindt relies on EthonAI's solution to model the relationship between the processes that lead to the perfect Lindor truffle. Armed with the resulting insights, the company can maintain the quality standard at a billion-unit scale.

EthonAI plans to invest the funds to develop its platform further and improve its offerings to meet customer demand, especially from customers planning to scale the MAS across several locations.

Comments